Cartridge housings type “4”

Cartridge housings type “4” are robust stainless steel filter housings which are modular and accordingly versatile.

The cartridge housings type “4” are robust stainless steel cartridge housings which can hold one single filter cartridge. These filter housings are modular, so the small number of basic types can be combined with individual components and options to create a large variety of application options. The use of stainless steel makes these cartridge housings not only ideal for filtering water.

The cartridge housings type “4” consist of two stainless steel parts: a head and a sump. The intake and outlet (internal thread) for the piping is located at the head. The head also houses the seating (cutting edge sealing) for the filter cartridge, the sealing O-ring and a sturdy external thread for the sleeve nut for screwing on the sump.

The head is available in two stainless steel versions – as a cast part or as a milled part from the lathe (“mechanical worked head”). The heads are interchangeable as they are compatible with all screw-on components.

The sump for 93/4” long or 191/2” long filter cartridges acts as the housing cover and is screwed onto the head finger-tight, then tightened slightly with a special housing wrench to ensure the housing is sealed and no liquid can emerge.

As a standard, the edges of the sumps are crimped outwards. The maximum operating pressure for these cartridge housings is 10 bar. Alternatively, sumps up to max. 40 bar are available, where the sleeve nut is welded on to easily resist the higher pressure.

With the corresponding internal pressure, unintentional opening of the cartridge housing during operation is not possible.

The sleeve nut is used to attach the sump to the head. Depending on the requirements and the area of application, two sleeve nuts (cast or turned) are available which are compatible with all heads and sumps. Sealing is provided by an O-ring between the sump and the sealing groove in the head.

Heads, sumps and sleeve nuts are interchangeable. The range is very flexible, but thanks to the modular design it can be limited to a few basic types of heads and sumps.

The cartridge housings are mounted in the pipe with the sump facing downwards. Special feet are not required. During filling, the air bubble rises to the head. The head has 1/8″ holes with bungs on the intake and outlet side for venting.

For mounting, holes are provided in both sides of the head, parallel to the pipe, intended for attaching the fixing brackets (optional).

Depending on the head, two internal threads with 3/4″ or 1″ intake and outlet are available.

The sump is available in two options: with or without 3/8″ sleeve for the drain plug.

The convenient drain plug can be released so the the cartridge housing can be drained before opening, e.g. for replacing the filter cartridge.

The 1/8″ holes in the head can be used to attach, e.g., vent valves or pressure gages.

The filter cartridges type “4” are suitable for filter cartridges open at both ends with the adapters DOE or P0.

Different options are available for seating the filter cartridges:

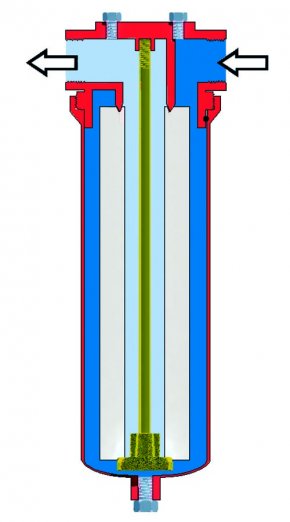

The filter cartridge is guided over the fixed center bar during installation and sealed with the pressure net (removal is carried out in reverse order). The prerequisite for this variant is that the sump can be removed downwards by the length of the filter cartridge. The filter cartridge is reliably seated and centered and the operator can ensure the correct position during installation.

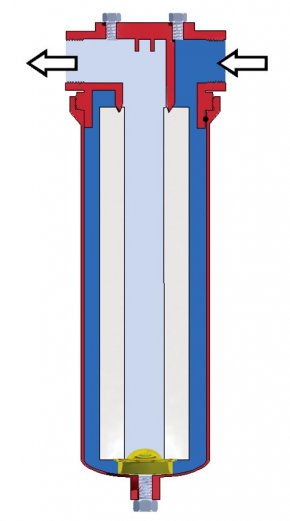

If the space underneath the cartridge housing is limited, the original form is normally used. The loose sealing cap is placed in the sump and the filter cartridge is placed on the cap. The sump with the filter cartridge is guided under the head from the side and pressed on the head.

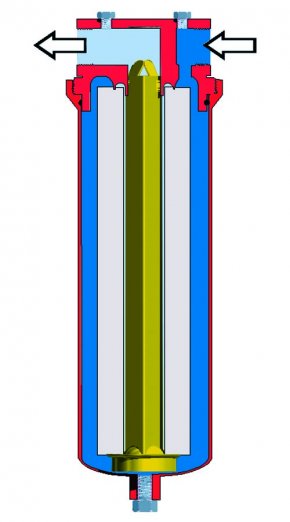

A combination of the two previous variants: A guide bar with a welded-on sealing cap is pushed into the filter cartridge and placed into the sump with the sealing cap facing downwards. The sump can also be guided under the head from the side and pressed down. The guide rod slightly protrudes beyond the edge of the filter cartridge so that the cartridge can be placed into the head accurately.

All three variants can also be retrofitted through conversion with the relevant components. This means that customers do not have to make a final decision on the best option at the time of purchase and can carry out tests if necessary.

Once the respective sump has been selected, all filter cartridges with both ends open (DOE, P0) and a length of 9 3/4″ or 19 1/2″ will fit into the cartridge housing type “4”.

The cartridge housings are supplied with comprehensive operating instructions containing a great amount of information and a spare parts list.

Putsch® offers the appropriate accessories for comfortable operation.

Box wrench for box nut (standard).

Hook wrench for special sleeve ring.

Two housing wrenches for the respective head (cast or turned part) are available.

Order the information package on Putsch® filter housings type “4” free of charge or download it directly here.

Brochure filter housings series 4

PDF, 1.5 MB

| Technical data | Cartridge housings type “4” |

|---|---|

| Head material | Stainless steel material no. 1.4571 or cast stainless steel |

| Sump material | Stainless steel material 1.4404 |

| Seal material | NBR, FPM, EPDM, FEP |

| Center bar & pressure cut | Cast stainless steel |

| Sealing cap/sealing cap with guide bar material | Stainless steel material 1.4404 |

| Inner surface | Pickled |

| Outer surface | Mechanically polished |

| Intake/outlet | Internal thread 3/4″ or 1″, flange DN 25 |

| Venting | Internal thread 1/8″ |

| Draining | Internal thread 3/8″ |

| Max. operating temperature/pressure | 90 °C at max.10 bar with water |

| Length of filter cartridges | 9 ¾“ or. 19 ½“ |

| Number of filter cartridges | 1 |

| Adapters | P0 (DOE) |

| Application examples | Water; chemicals; paint and varnish; installation in various systems as a safety filter, e.g. in cleaning systems; ultrasonic baths |

Design as per PED 2014/68/EU, art. 4 par. (3), good engineering practice for group 2 liquids.

Cartridge housings type “4” are robust stainless steel filter housings which are modular and accordingly versatile.

Cartridge housings type “6” have been used widely in all industries for over 40 years and are particularly popular due to their solid, robust quality.

Cartridge housings type “D” and “D-G” from Putsch® are manufactured individually to meet the requirements and special requests of customers.

Cartridge housings type “Sanitary” are stainless steel cartridge housings which are ideal for filtration with a high level of hygiene requirements.

Housings type “SM”, “SL” and “PN” are polypropylene cartridge housings for use as water filters, each with individual filter cartridges. Their low weight makes them ideal for mobile water systems.

Cartridge housings type “BB” are made of polypropylene and designed for special filter cartridges with a larger diameter which have particularly long service lives.

The customized cartridge housings type “D-PP” are made of polypropylene and are used wherever comparable metal housings are unsuitable, e.g. in an environment containing salt.

Use our extensive range of services for solid/liquid separation. Your contact can help you with any questions and problems.

Please send any inquiry and order to filtertechnik@putsch.com.

| Phone: | +49 (0) 23 31 / 3 99 1 53 |

|---|

Customer Service Center

| Phone: | +49 (0) 23 31 / 3 99 – 1 50 |

|---|

Emergency number

If you need to contact us in emergencies outside office hours, the responsible Putsch® employee will be informed immediately and the required measures for solving your problem will be initiated.

| Phone: | +49 (0) 23 31 / 3 99 – 0 |

|---|

Putsch® offers a very large selection of string-wound filter cartridges in many sizes, designs, materials and winding patterns.

The depth filter cartridges type “HP” from Putsch® are special depth filters on polypropylene basis which are known for their particularly long useful life.

The depth filter cartridge type “CX” is a 3D absolute filter for customers with very high cleanliness requirements.

The Putsch® depth filter cartridges type “K11” with their micro-polypropylene filter matrix are known to be particularly effective and are especially suitable for filtering out ultrafine particles.

Putsch® metal mesh filter cartridges type “MGG” + MGP” are special stainless steel cartridge filters for operation at high temperatures or with specific chemicals.

Putsch® activated carbon filter cartridges type “PA-G” are equipped with steam-activated coal pellets and specially designed for strongly contaminated liquids.

Putsch® filter cartridges type “PRO” are cartridge filters on the basis of phenolic resin-bound acrylic fibers, designed for the special requirements of paint and varnish filtration.